I did not gain a half a point, but the chambers were a little larger than 100cc on average (before cutting) and the added volume of the gasket took away a little as well. The CR I calculated worked out to be about 9.55:1 with a Fel-Pro gasket at. 108.:beers: The additional volume does not hurt my CR that bad. 065 9 degrees after TDC, and now I have about. I also measured the volume of the new valve relief as I cut them to ensure the cuts were equal.

I took some pics that I could post if anyone is interested, but they look just like the ones that Vince posted with the exception of the tool. Actually, as crazy as this sounds, it has been one of the easiest things I have done with this motor so far.

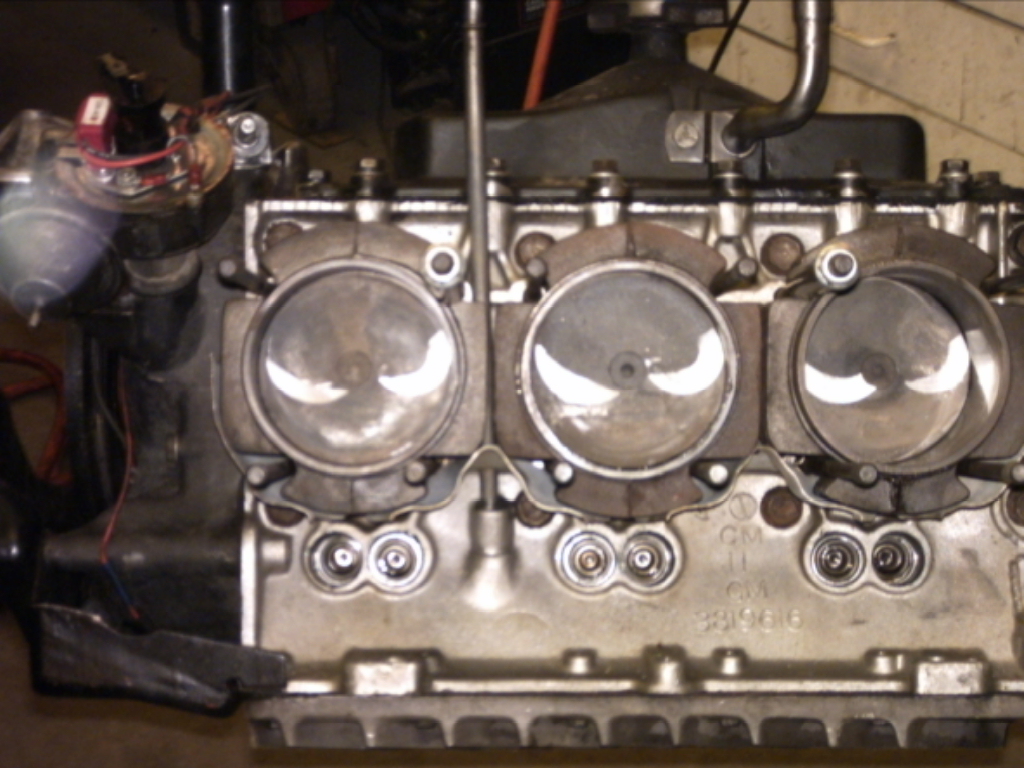

I basically followed the steps outlined by Vince (thanks again for the pics) and it worked very well. The Sherline fly cutter comes complete with the holder, a drawbolt, thrust washer, and a. 010 (.25 mm) deep cut in aluminum at this diameter. The cutter can be adjusted to cut up to a 2.00 (51 mm) diameter and is easily capable of taking a. PLEASE CALL WHEN ORDERING IF YOU ARE NOT SURE WHAT FLY CUT. I received the tool from ET Supply and was very satisfied with the quality. The fly cutter is a single-point cutting tool similar to a lathe tool mounted in a special holder. FLY CUTTING PISTONS IS DONE FOR INCREASED VALVE CLEARANCE WHEN RUNNING LARGER THAN STOCK CAMS.

Piston flycut tool update#

I thought I would post an update as the motor is mostly assembled now.

Piston flycut tool windows#

Especially if the exhaust valve has a ton of room. Case Boring and Cylinder Head Flycutting Tool, EACH lets you open up the cylinder windows in your case and heads You can also flycut the heads for more. I think the first thing I would do is start from scratch and check the cam degree again. Best for fine finishing surfaces with cut depths of up to 0.030' in steel and 0.080' in aluminum and plastics. Body & bars are cryogenically treated for stability. Body & bars coated with clear zinc for corrosion resistance. The pistons have to come off the rods, even though I do know one guy that has a fixture for doing them on the rods, but it is a pain in the rear end Cutter body fits shell mill arbor with 1' boss & 3/8' key. This way you dont have to cut any more than really needed. If everything is correct and you have to get the pistons flycut, what I like guys to do is get the piston to the point of closest clearance, usually a little before or after tdc, then take the head off and remove the valve and use a transfer punch down through the guide to mark the top of the piston. The cutout might be deep enough, just not big enough in diameter.ĭid you have a head gasket on when you checked it ? that will give you another. It might be just hitting the edge of the valve relief. How much room did the exhaust have ? Also, you need to put some clay on and see exactly where it is too close. I really wonder if you have the cam degreed right, even after your previous post. 625 cams in Mercruiser flat top engines and never had any type of clearance issues.

0 kommentar(er)

0 kommentar(er)